High Efficiency Heat Pumps & Air Conditioners

High Efficiency? You may want to think twice!

With utility costs soaring higher and higher today everyone is looking for ways to save money. Since the A/C system accounts for 25-50% of the average summertime electric bill, it is a likely target for improvement. One idea that frequently comes to mind is getting a "high efficiency" air conditioning system. Oftentimes a higher efficiency system can save a considerable amount of money. However there are many variables to take into consideration when deciding whether to opt for a high efficiency system though. Some of those variables include the following:

- Difference in initial cost of a standard VS high efficiency system

- The dependability of a complicated new system

- The longevity of a system with new technology

- The repair costs during and after warranty ends

- The availability of parts in the future

- The availability of qualified technicians to service complicated systems

Note: SEER is an acronym that stands for Seasonal Energy Efficiency Rating. It is a measurement of cooling output VS wattage consumption. The higher the SEER number, the higher the efficiency. As of the writing of this article, the federally mandated minimum residential SEER2 for Arizona is 14.3. SEER2 is a new method of calculating efficiency that utilizes more stringent parameters for testing than the original SEER rating.

Let's go through each of the 6 points shown above.

POINT 1 - COST There is a considerable cost difference between a standard efficiency unit and one that is above that. A 14.3 SEER2 unit of a particular size and type may cost, let's say for the sake of example, $5000. To upgrade that same installation to an 18 SEER2 system may cost let's say $8000. So the difference between 14 and 18 SEER2 may be $3000 in this imaginary example. Now we have to calculate a lot of other things into that $3000 to get a true picture. First off of course is the cost of money. If the money is borrowed, there is interest. If the money is paid in cash, there is the loss of interest or dividends that money could of otherwise provided. Either way, the $3000 has a considerable cost and a value.

Most people assume the extra savings in electricity will pay for the $3000 (or $4000, 5000 or whatever the value is that we calculate that money to cost over the life of the system) investment over time. You would think that it does, but the numbers really don't seem to add up in most cases, at least not without adding on utility rebates and tax incentives and manufacturer or contractor discounts. To get those utility rebates may require spending considerably more to comply with their "quality" installation requirements and may require you to have an air conditioner model that is marginally sized (too small, running NON-STOP during extreme temperatures). Utility companies offer rebates for high efficiency installations but they mandate that the contractor doing the installation performs a cooling / heating load calculation to determine the size of the unit you will get. The required ambient temperature design parameters (for Phoenix, AZ area) for those calculations are 108 degrees! This is absurd and very unrealistic, especially considering that the climate is changing and consistently getting hotter. As a contractor I am profoundly offended that I alone maintain FULL responsibility for the A/C installation being sized to properly and adequately cool and heat yet in order to participate in this program the utility company dictates the size of the unit I have to install. This is beyond ridiculous and a substantial conflict of interest! On top of that they require a minimum 16 SEER to qualify which may require a substantial investment. In any case, it is a moot point since the utility savings does not cover the typical difference in cost anyways. Take a look at a calculation performed recently on a name brand A/C manufacturer's website.

In the example shown (average sized residential unit in Phoenix, AZ), the electric savings over a 15 year period is slightly over $2300. If the cost difference between a 14.3 SEER2 and an 18 SEER2 was only $2300 and the money fairy gave you the money interest free to repay over the 15 years period, it would still be a horrible investment! In reality there is no money fairy and the difference is likely much more than $2300, and so in my opinion this is a bad idea financially. It is a net loss. It is a liability. It is a huge gamble and risk. There are simply much better ways to utilize that money instead of losing it to technology.

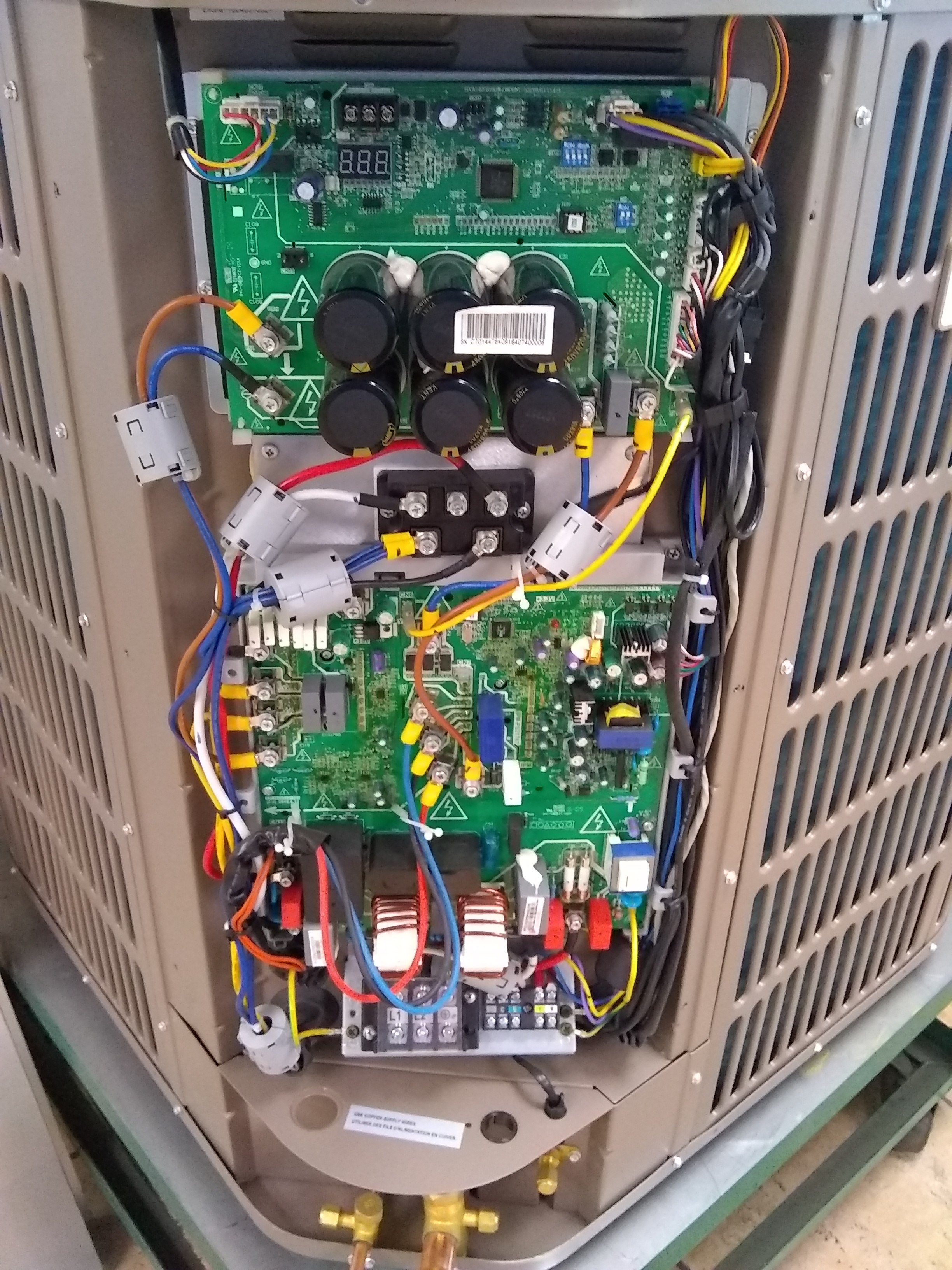

POINT 2 - DEPENDABILITY The "high efficiency" technology used in most air conditioners over 16 SEER2 is generally going to be an inverter. Take a peek inside a new 18 SEER2 air conditioner below. Looks complicated huh?

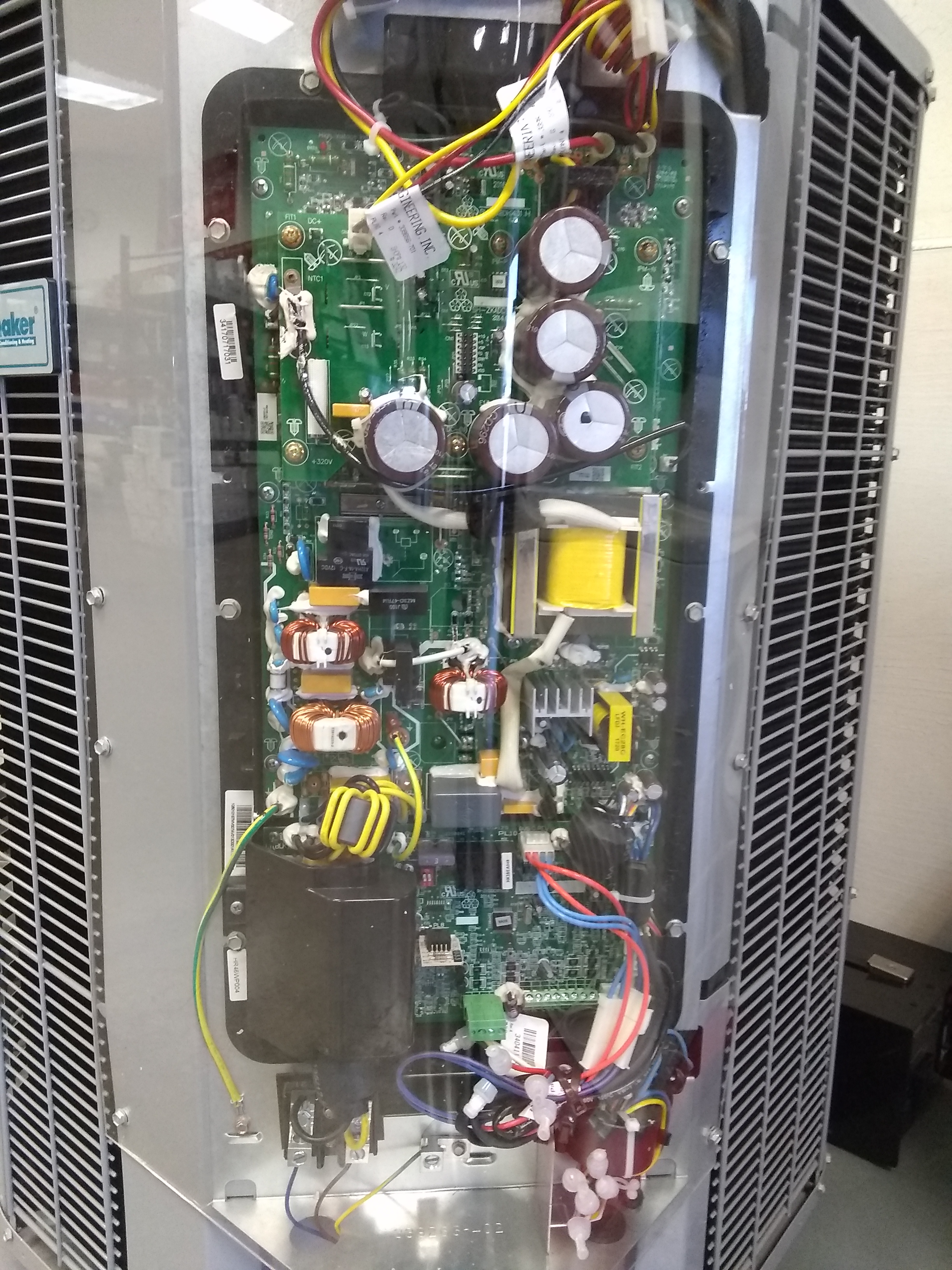

Take a look at the electronics inside another new high efficiency unit below. Looks even more complicated!

Look carefully at those GIGANTIC circuit boards! It is hard to tell from the pictures, but the circuit boards are approximately 2 feet high and 1 foot wide. That's approximately 2 solid square feet of electronics! Do you really think this is dependable? Does it look dependable? Everything inside there is high tech and extremely complicated and only an electronics genius would know how it works. There is nothing in there that is field serviceable by an A/C technician. If it works, then it works. If it doesn't work then a technician is going to have to call a technical support hotline to talk them through the test-out procedure and after a lengthy conversation they will determine that it probably needs to be replaced, the WHOLE circuit board. At least with a standard air conditioner there are many separate components inside the electrical compartment that are individually serviceable by a field technician. If one small part goes out it can be easily and inexpensively replaced, oftentimes even using a universal replacement part that fits many different brands. If a capacitor goes out, the tech can replace it in about 10 minutes. If the contactor goes out, it may be a 20 minute jobs perhaps. Many parts are easily replaceable on standard efficiency systems. With the circuit boards above though, everything is electronically integrated into ONE part that will require an exact replacement circuit board if it goes out. Does this sound like a great idea to you? Does this look like something you would want to buy? This is certainly NOT something a technician is going to come out and fix in 20 minutes! It could take 20 hours, or even 20 days if the part has to be ordered from the factory (and it probably will).

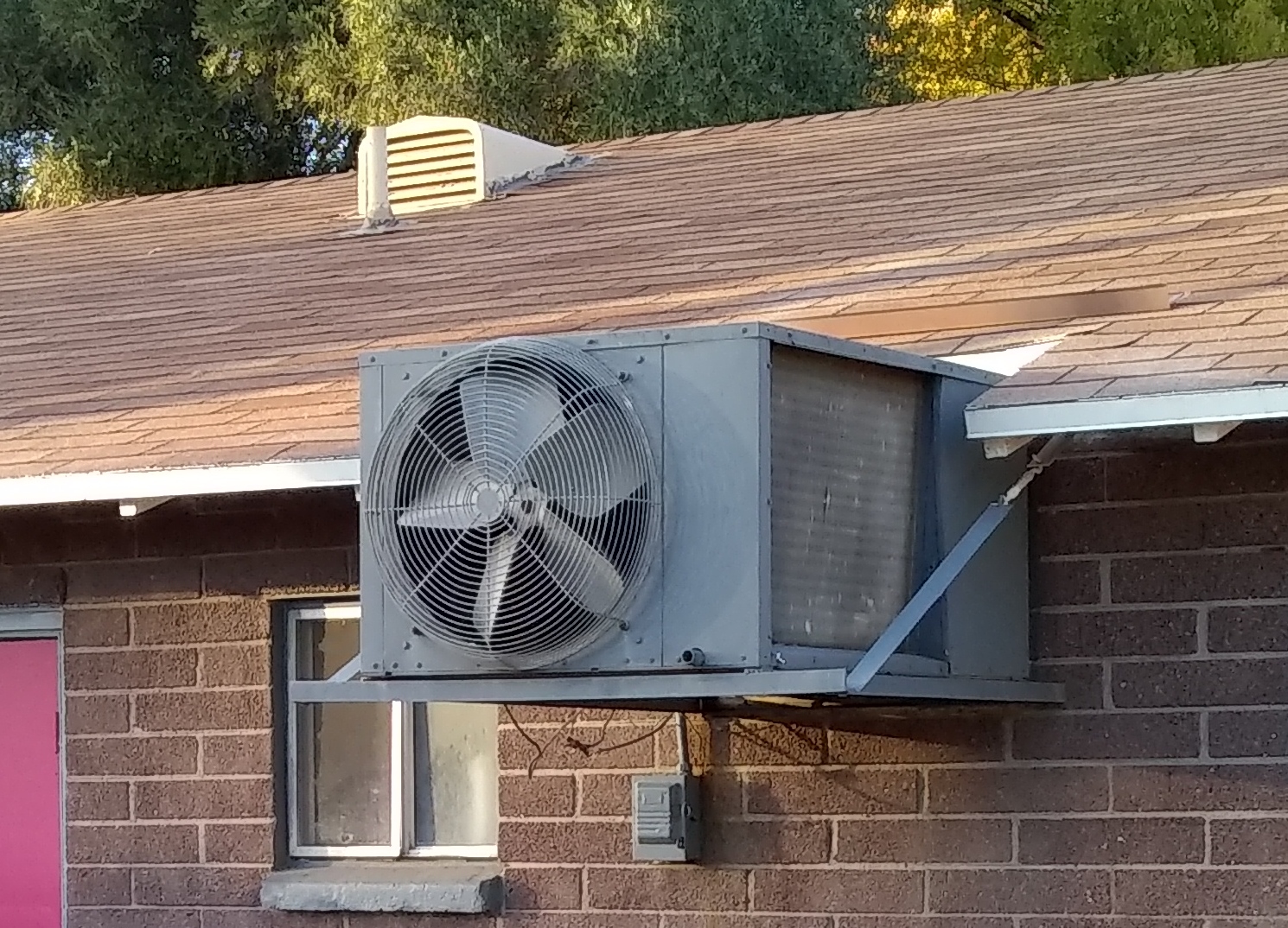

POINT 3 - LONGEVITY How long will these systems last? There are many systems manufactured in the 1970's, 80's and beyond that are still in service today, still working just fine. In fact, I personally know of an apartment complex in Tempe that has several original Goettl Bros. first generation air conditioners from 1963 (not to be confused with the LLC organization from Nevada that is presently using the name locally) still operating! That's an incredible over 60 years of continuous service. Take a look at a pic below of one of their units still in service (as of the writing of this article).

I do not have a magic ball that tells me the future, but one thing I can tell you very definitively is that a new air conditioner will never have that level of longevity, even a 14.3 SEER2. And there is absolutely no way a new high efficiency system over 14.3 SEER2 will be working when it is 60 years old. I GUARANTEE that! Not even 1 percent will still be working in 60 years. My guess is that not even 1/10 of one percent (that's 1 out of a thousand)! Quite a few 14.3 SEER2 systems however may still be working (after many repairs though, I'm sure).

POINT 4 - REPAIR COST In my opinion a high efficiency system is going to be very problematic for the owner in the years following installation. The extremely complex and sensitive electronic components are no match for the hot Arizona climate and they simply will not last. It seems to me that it is a really bad idea to put expensive electronics inside an air conditioner that is subject to extreme heat, extreme vibration, extreme dust and extreme usage. In addition to all those factors the A/C units in Arizona are even exposed to cockroaches, scorpions, spiders, ants, pigeons, rodents and other pests that like to nest inside them, ESPECIALLY inside the electrical compartment. Some technicians have even reported finding live snakes. Electronics do not respond well to the presence of these pests. On top of all that we get monsoon storms that can cause electrical spikes that can kill electronics in a split second, frying it to a smoking crisp. High efficiency A/C units have lots of fragile electronics that will not like our violent monsoon storms. Take a look at this litter critter found inside of the electrical section of an air conditioner in Phoenix.

You might say, what about the 10 year warranty? Should I even worry about repair costs since the warranty is so long? Yes! Definitely yes! There is a chance that you don't actually have 10 years of coverage. To obtain 10 years the installation must be registered with the manufacturer within 60 days (telling them the owner's name, location of installation, name of the contractor, etc.) and either the installer or the customer MUST complete the registration. Many times this is overlooked or simply forgotten, and in this case you only have 5 years of warranty coverage, limited of course. The warranty does not cover damage of any kind or lack of maintenance. It also does not cover labor (usually the installing contractor will offer a labor warranty for one year only). Even if the parts are covered by warranty, the labor charges and charges for parts / items not under warranty coverage (refrigerant, wiring, tubing, thermostats, fuses, etc.) can get very expensive. Sometimes when a customer gets a lemon unit they will give up on a unit still under manufacturer warranty because they don't want to waste any more money on it. I think this will become a very common scenario with many high efficiency systems in the future. All I can say is caveat emptor (let the buyer beware)!

POINT 5 - PARTS AVAILABILITY Not only will a high efficiency system not be working 60 years from now like the old Goettl Bros. system mentioned above, in my opinion many of these new high end / high efficiency systems being sold today won't even be in service 25 years from now! Some of them perhaps not even 10 years from now. They will be replaced because the owner simply gives up and decides to stop dumping money into a losing battle with a hopeless complicated technological nightmare air conditioner. Many of the parts that high efficiency systems use are proprietary and unique, and since the technology is evolving so rapidly now with so called "improvements" and "advances" the parts being used one day might not be the same ones they use the next. This is a recipe for limited availibility (supply issue) and PRICE GOUGING (demand issue) on the part of the manufacturer. The circuit boards, the motors, the compressors and even the thermostats sometimes are often unique and specific for a particular model only. There are no substitute parts that can be alternately used, only OEM specific parts will work, without rigging and butchering the system with unauthorized parts. By the time the parts go through the multi-leveling marketing trek from factory to distributor to servicer to the end user lots of people have added a new profit to the final price before the cost is tallied. A $250 circuit board will cost the customer $1500 or more plus labor! Wow, that is crazy but it is a very realistic scenario. On top of that it is very probable that when one of these special proprietary OEM parts needs to be replaced the part must come from the factory as a special order. It almost certainly will not be in stock locally and will have to be shipped here. Would you really want to wait for shipping for a part to fix your air conditioner in the middle of summer when it's 115 outside?

Another thing to consider is that since the recession of 2008, it has become commonplace for manufacturers to stop making low demand specialty replacement components for equipment beyond the 10 year warranty period. It simply isn't profitable to continue manufacturing parts that are expensive to build and maintain in inventory if there isn't a large enough demand for them. I asked a distributor about this one time recently while inquiring about a brand-specific / model-specific component for a system that was barely over 10 years old, and they told me that it is simply noted as "obsolete" on their computer database. In other words, the manufacturer was saying we don't have parts for you anymore, so just make your customer buy a new system instead. In my opinion many of the parts for these new high efficiency systems will end up in the "obsolete" category very soon after the warranty expires. Good luck fixing something that parts don't exist for anymore!

POINT 6 - FINDING QUALIFIED WORKERS Do you know how difficult it is to find a good HVAC technician? It is nearly impossible. The truly qualified technicians either ascend to management positions or they start their own companies. Very few are working in the field as an employee for a company. The ones who are good techs are usually assigned to babysit the rest of the incompetent people that work at the same company and you will only get these techs coming out for your service call in the winter after the company lays off all the incompetent ones, or you will only see them in the summer after the incompetent techs have failed to fix the problem and it has become an issue. The majority of the technicians working in the field today are mediocre, at best, and make lots of mistakes. They hardly know how to repair a basic standard efficiency air conditioner, let alone a high efficiency one. The odds of calling any particular company out (even the so called "big guys" on the freeway billboards, on the top of page one search results and on the radio 50 times a day) to work on your 5 year old or 10 year old high efficiency air conditioner and having a good experience are not very good. You probably have better odds of buying a scratch lottery ticket and winning $20. Seriously, for real.

Another interesting thing occurring today that dilutes the quality of the technical workforce is that companies are "dual" positioning their workers in some cases. Lots of companies are cashing in on their success in one industry by attempting to increase the monetary return from their customer base by expanding into additional trades. For example, there are lots of A/C companies who now do plumbing too. There are even some A/C + plumbing + electrical companies emerging now. In my opinion this trend will continue as companies today become less about professionalism and delivering a quality product with their expertise in a particular field and instead become focused on monetizing their customer base and maximizing their advertising return. While sometimes these new multi-trade companies have dedicated tradesmen for each type of service they provide, it is easier and much more cost effective to cross train a plumber to also repair air conditioners, or cross train an HVAC tech to also do plumbing service. Frankly speaking, the odds of any one single person being proficient at just one trade are very poor, and to have someone proficient at 2 or more trades is almost an impossibility. Of course there are "tech support" hotlines that a technician can call from their cell phone and access help if they can't figure out what they are doing, but do you really want to pay somebody to sit on the phone to figure out what is wrong with your air conditioner? They really should just know what they're doing before they take on a job. To me it seems like a really bad idea to have plumbers fixing an air conditioners! It seems an equally bad idea to have HVAC techs working on your plumbing. Let a REAL plumber with years of plumbing experience fix plumbing, and likewise a real HVAC tech with years of experience fix the air conditioners.

There Are Different Types of "High Efficiency"

One important thing to consider is that today (as of the writing of this article) the federally mandated minimum efficiency standard for new packaged and split residential central A/C systems in Arizona is 14.3 SEER2. While many of the new high efficiency systems go well beyond the current minimum rating, a 14.3 SEER2 unit is actually already quite efficient. In fact, by comparison this is DOUBLE the efficiency of many older systems still in service. And this is only the minimum! If you need to replace your old air conditioner, a 14.3 SEER2 unit is going to be a considerable improvement over what you have now. Even if your existing unit is a 10 SEER or 12 SEER, it is likely not functioning anywhere near that level of performance. Studies have shown that a 25 year old air conditioner can lose 25% or more of its efficiency and still be cooling and heating just fine.

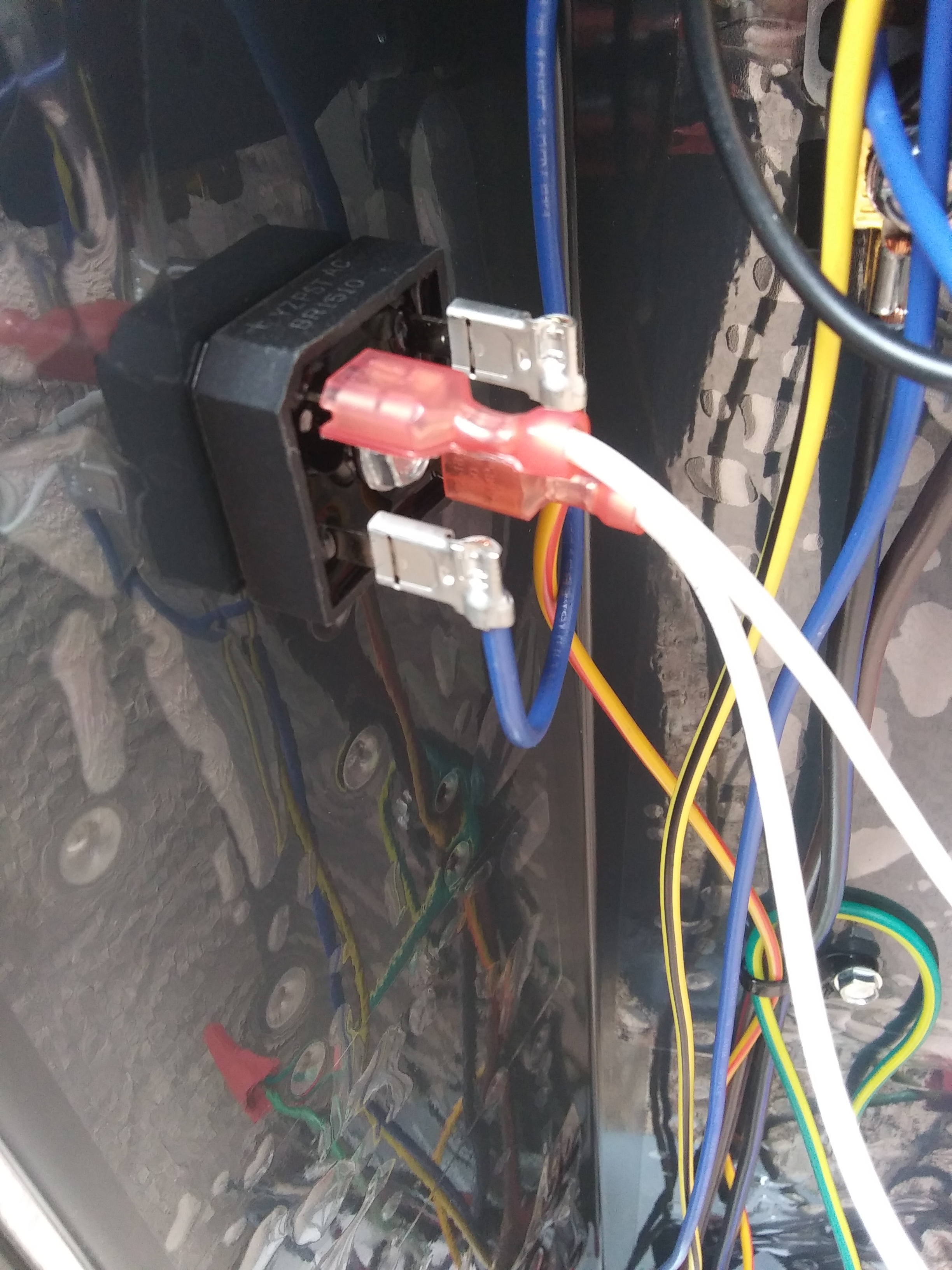

If after considering all these points you are still interested in a system higher than 14.3 SEER2 then we recommend a 2 Stage A/C system. 2 Stage is very different than variable speed systems (inverter) or even 2 speed systems. A 2 Stage system uses one single compressor, one single speed. In this regard it is just like any other standard efficiency compressor, but it has an accessory component built into the design by the manufacturer that enables the compressor to have 2 pumping capacities, a partial and a full load. This is accomplished by a simple solenoid that is switched either on or off. The solenoid controls a bypass port in the compressor. While the compressor motor runs at a constant speed, the bypass mechanism controls the capacity of the compressor, thus providing two capacities, or stages. It is controlled by a small rectifier. Below is a pic of the "electronics" circuitry used in the Trane 2 stage system. It's hard to gauge from just looking at the picture, but the entire recifier is only about 1" square.

This is very similar to the unloader technology that has been used in commercial A/C and refrigeration with complete reliability for more than a half of a century. This technology is time-tested and proven to be very dependable. The 2 stage compressor technology is far superior to variable speed or multi speed technologies in that it is extremely simplistic. In our opinion, a 2 stage system is far more likely to still be functioning when it is 10 years old than any other comparable SEER system will be. Even if the staging mechanism fails, the compressor will likely still function at partial or even capacity. As a general rule, the more complex a system is, the more problematic it will be. American Standard and Trane offer a 2 Stage system in their product line, in both packaged and split applications.